Da könnt ihr euch vorstellen was bei AUO oder Samsung bei der Produktion falsch läuft:

"The washing process is performed to get rid of the particles from the surface of the glass substrate.

The methods of washing process are as following; washing with chemical, washing with ultraviolet rays, washing with pure water, and others, it will be selected by the most suitable washing method according to the condition of the glass substrate surface."

Bezüglich der Qualität eines Panels:

"In the cell process, the alignment of liquid crystal and injection of the liquid crystal materials between the color filter coated glass substrate and the transparent electrode patterns coated glass substrate are processed, and the liquid crystal materials are sealed between the glass substrates.

These processes are important because it affects the display quality of the LCD.

The manufacturer selects the liquid crystal mode from TN, VA, IPS, and so on, according to the use, for example TV, mobile, etc. Therefore, according to the each mode, the optimization of the alignment process is necessary.

Furthermore, according to the ultra high accuracy of the pixel of the LCD these days, the alignment technology has been progressing."

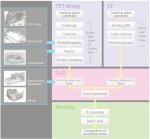

Hier der ganze Produktionsprozess als Schema:

Irgendetwas muss bei cleanen und coaten falsch laufen. Bezüglich der restlichen Bugs (besonders temperature shift) wird vermutlich bei dem Auftragen der Flüssigkristalle geschlampt.

Grobe Erklärung des Herstellungsprozesses:

"LCD manufacturing process consists of the array process, color filter process, cell process, and module process:

In the Array process, the transparent electrode patterns which drive the liquid crystal and the signal lines are made onto the glass substrate.

In the color filter process, the color filters are made onto the glass substrate to form the 3 primary colors, which are red, green, and blue.

In the cell process, the alignment of liquid crystal is formed, and injection of the liquid crystal materials between the glass substrates are performed, and the liquid crystal materials are sealed between the glass substrates.

In the module process, the driver IC and the back light are installed to the glass substrate."

So sollte normalerweise der cleaning room aussehen.